Product Features:

Flexible Configuration

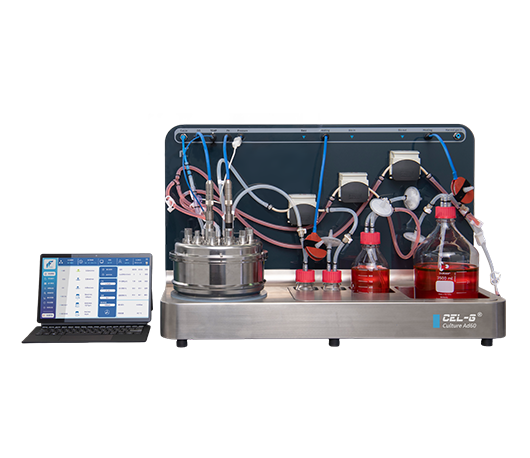

- Stainless steel 316L table-top unit suitable for fixed-bed tanks of different sizes.

- Effective cell growth area: 2m2, 20m2, 60m2, scale up.

- Low footprint and can be used inside a biosafety cabinet.

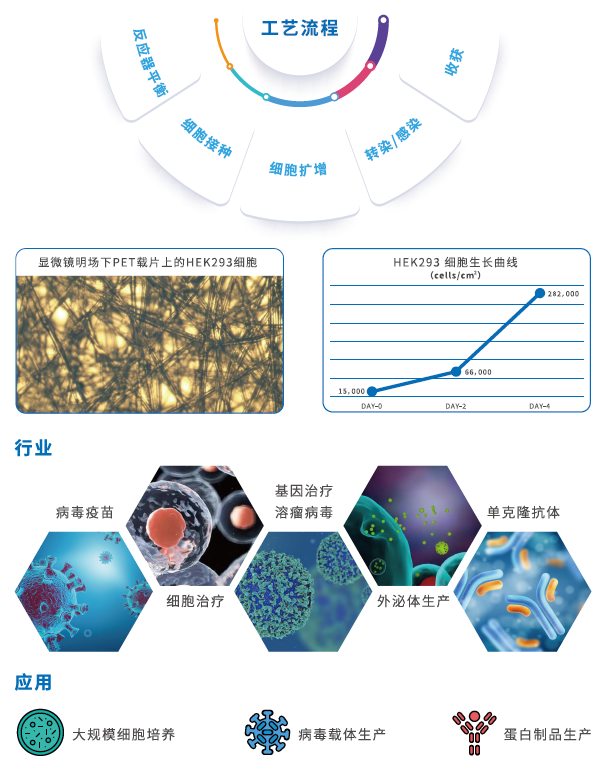

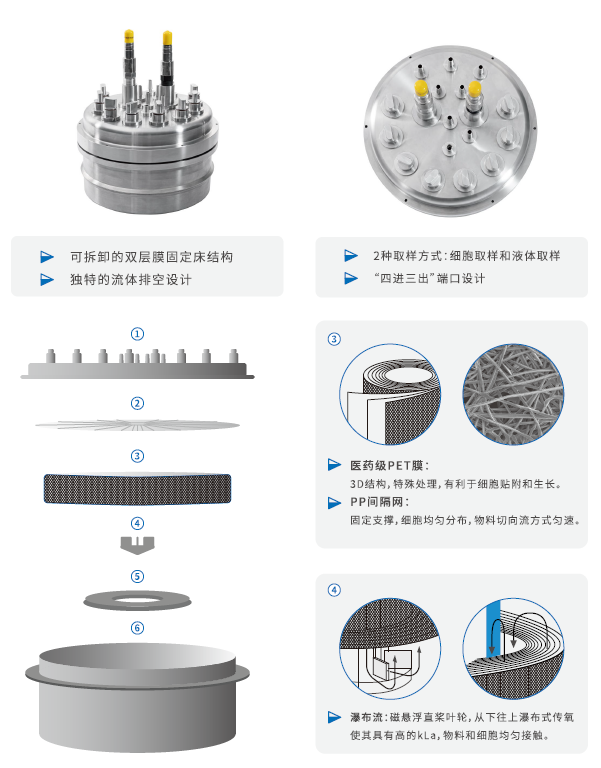

- Pharmaceutical-grade PET membranes provide a 3D microenvironment for cell growth.

- Shear force, gentle and friendly to cells and products.

- Dual internal and external circulation allows for batch mode, recirculation mode and perfusion mode.

- Flexible and safe sampling for process characterisation.

- Powerful in-house algorithms for easy multi-parameter control of the incubation process.

- High degree of automation with on-line coupling to downstream processes.

Product Application: